Roof Assemblies

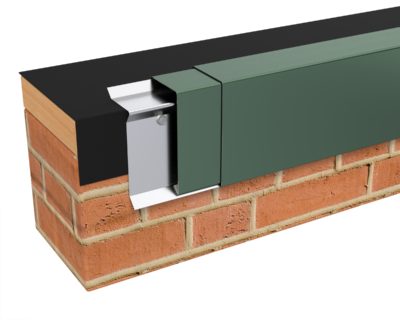

DOUBLE-LOCK can be applied over various roof substrates including: open framing, rigid insulation (utilizing a bearing plate under each panel clip 30” o.c., max.) over 22 ga. steel deck, and various solid substrates including plywood sheathing and nail base insulation.

Uses & Applications

Product uses include barrel vaults, curved canopies, low to high slope roofing, and mansards.

Product Offerings

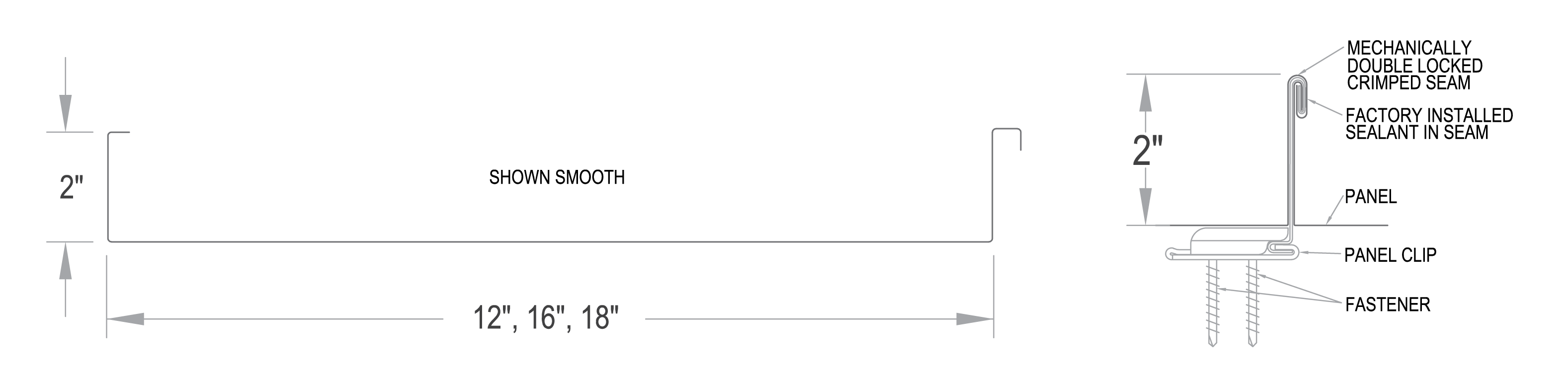

24 ga., 22 ga. Steel, and .032, .040 Aluminum

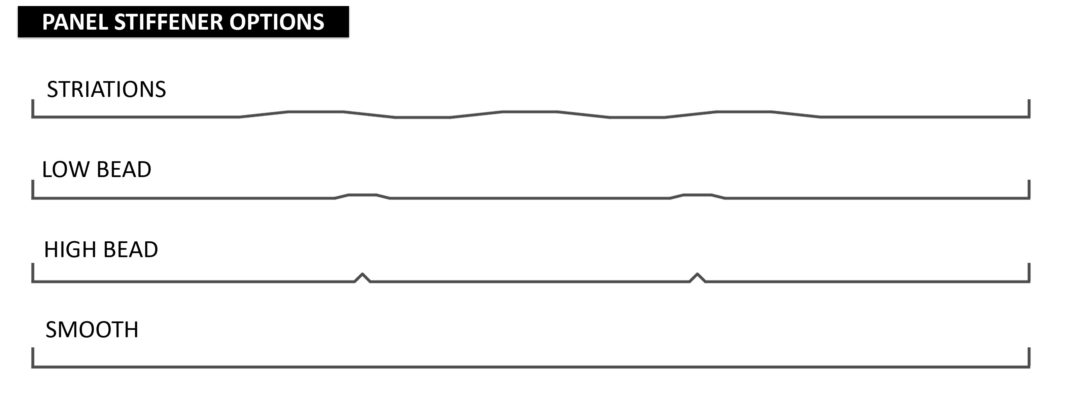

Embossing and various stiffener configurations available

- DL2012 with 12″ o.c. seams

- DL2016 with 16″ o.c. seams

- DL2018 with 17.625″ o.c. seams

16, 20 oz. Copper

Various stiffener configurations available

- DL2012 with 12″ o.c. seams

- DL2018 with 17.65″ o.c. seams

Note: Other widths available. Contact DMI for questions.

Performance Tests

- UL-580 Wind Uplift

- ASTM E1592 Uniform Static Air Pressure

- ASTM E1646 Water Penetration

- ASTM E1680 Air Leakage

Load Tables:

Advantages

- Factory Applied Non-Curing Sealant: For superior watertightness

- SMACNA Seam Design: A traditional and historical aesthetic appearance

- Expansion Clips: Allows for thermal expansion and contraction

- Continuous Rollformed Lengths: Eliminates need for panel lap joints

- Total System Warranties Available: For total confidence

AIA Continuing Education

AIA Continuing Education

DMI is committed to providing you with high-quality expert-level education in accordance with the AIA/CES standards. The courses we offer are designed to meet the needs of architects and typically run one hour in length. All Attendees will earn 1 Learning Unit. Some of the courses offered will meet the Health, Safety, and Welfare (HSW) requirements as well as the Green Building Certification Institute (GBCI) credits.

Our Warranties are Second to None

DMI total system warranties protect all aspects of your metal envelope system, whether that be the watertightness of the roof or siding, the Galvalume ® steel, or the durable PVDF KYNAR® finish. When looking at warranties for your system, it is important to note that not all warranties are created equal. DMI warranties ensure the watertightness of all flashing conditions, trims, curbs, valleys, and penetrations. Building owners are protected with a total system warranty - “from the deck up” when using DMI insulation, fasteners, and underlayment. Our warranties are backed-up by a full-service Engineering Department, generating project specific shop drawings. Quality control is monitored by a minimum of two on-site inspections by our Field Technical Inspectors. DMI Total System Warranties give building owners and design professionals confidence that they are receiving the highest quality and most complete warranty available in the industry.