RUBEX 126 Premium Butyl Tape Sealant

Rubex 126, manufactured at the Rubex facility, is a premium butyl tape formulated to provide optimum sealing properties and adherence to a variety of substrates. It will reduce or prevent electrolysis, galvanic corrosion, thermal transfer, vibration, and noise transmission.

Rubex 126, manufactured at the Rubex facility, is a premium butyl tape formulated to provide optimum sealing properties and adherence to a variety of substrates. It will reduce or prevent electrolysis, galvanic corrosion, thermal transfer, vibration, and noise transmission.

Rubex 126 meets or exceeds the following specifications: MIL-C-18969B TIICB, TT-C-1996A TIICB, AAMA 804.3-92, and AAMA 807.3-92

DOWNLOAD RUBEX 126 CUT SHEET

Product Uses

Rubex 126 bonds through oily Galvalume; and also adheres well to Zincalume, KYNAR 500, painted metals, glass, wood, and concrete. As such, it is a standard in the metal building, roofing, and construction industries. It is commonly used to seal: roof curbs, Standing Seam Roof endlaps, metal rib and lap joints, sky lights, window and door flanges, air conditioning units, polyethylene sheeting, and rivet and lap seams in trailers and RV’s.

Technical Information

- Tensile Strength (ASTM C907): 15 – 18 psi

- Cone Penetration: 8.0 – 9.5 mm @ 77oF

- Color: Off-white

- Specific Gravity: 1.55 – 1.65

- Elongation (ASTM C908): >1000%

- Application Temp. Range: -5oF – 120oF

- Service Temp. Range: -40oF – 200oF

- Water Penetration (ASTM E2140): None

- Solids Content (ASTM C771-74): 100%

- Low Temp. Flexibility: No Adverse Effects

- Sag (AAMA 800): None

- Peel Adhesion (ASTM D3330): >8 psi

- Staining: None

- Shelf Life: 18 Months

Application Information

To facilitate handling, Rubex 126 is extruded onto removable release paper backing. For most efficient usage, ensure all involved surfaces are clean and dry, although light films of lubricant on unpainted metals should not adversely affect performance. Once ready for application, it is recommended that the material be pressed onto one surface, stripped of its paper backing, and then brought into contact with the second surface. When using to seal applications involving fasteners, position on the entry side to prevent the penetration of contaminants through fastener holes.

Packaging & Handling

Rubex 126 is available in a variety of different widths, thicknesses, and profiles. It is manufactured in both roll form, and in customer specified strips. No special handling is required for this product, though storage in a cool, dry area is recommended for maximum shelf life and effectiveness. Tools and equipment used while applying Rubex 126 can be cleaned using mineral spirits, if necessary.

Safety Instructions

No special requirements are needed. An MSDS is available upon request.

AIA Continuing Education

AIA Continuing Education

DMI is committed to providing you with high-quality expert-level education in accordance with the AIA/CES standards. The courses we offer are designed to meet the needs of architects and typically run one hour in length. All Attendees will earn 1 Learning Unit. Some of the courses offered will meet the Health, Safety, and Welfare (HSW) requirements as well as the Green Building Certification Institute (GBCI) credits.

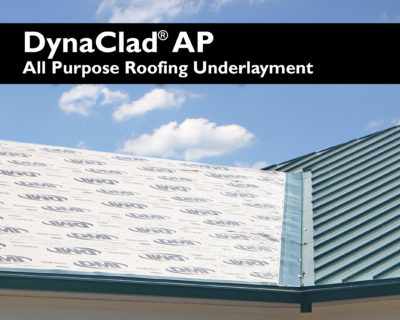

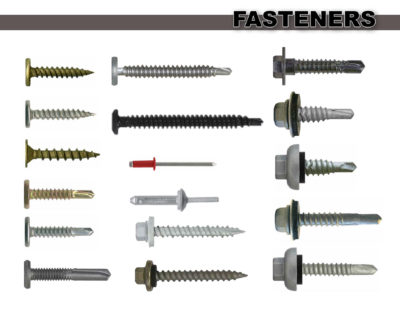

Our Warranties are Second to None

DMI total system warranties protect all aspects of your metal envelope system, whether that be the watertightness of the roof or siding, the Galvalume ® steel, or the durable PVDF KYNAR® finish. When looking at warranties for your system, it is important to note that not all warranties are created equal. DMI warranties ensure the watertightness of all flashing conditions, trims, curbs, valleys, and penetrations. Building owners are protected with a total system warranty - “from the deck up” when using DMI insulation, fasteners, and underlayment. Our warranties are backed-up by a full-service Engineering Department, generating project specific shop drawings. Quality control is monitored by a minimum of two on-site inspections by our Field Technical Inspectors. DMI Total System Warranties give building owners and design professionals confidence that they are receiving the highest quality and most complete warranty available in the industry.