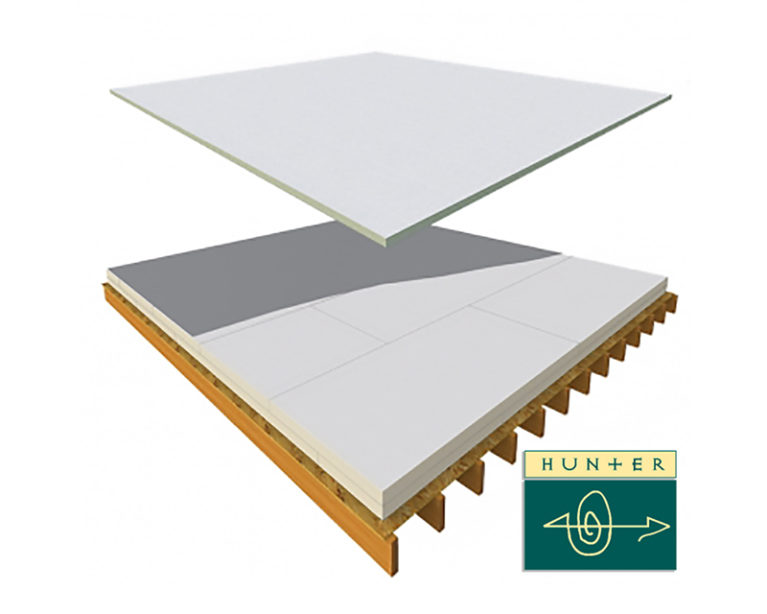

H-Shield CG

H-Shield CG is a rigid roof insulation panel composed of a closed cell polyisocyanurate foam core manufactured on-line to a premium performance coated glass facer on both sides (CGF).

Features and Benefits

- Manufactured with NexGen Chemistry: Contains no CFCs, HCFCs, is Zero ODP, EPA Compliant, and has virtually no GWP

- Provides improved dimensional stability, fire performance and resistance to mold growth. Passed (10) Resistance to Mold test ASTM D 3273

- Achieves a Class A combustible deck assembly rating without the use of a fire rated slip sheet or the presence of a gypsum cover board when applied at a thickness of 3″ or greater in a single layer or in combination of multiple layers (i.e.: two layers of 1.5″)

- Achieves a Class A combustible deck assembly rating without the use of a fire rated slip sheet or the presence of a gypsum cover board when applied at a thickness of 2.5” or greater in combination of a minimum base layer of any 2.5” Polyisocyanurate insulation.

- Achieves a Class B combustible deck assembly rating without the use of a fire rated slip sheet or gypsum cover board when applied at a thickness of 1.9″ or greater in a single layer

DOWNLOAD H-SHIELD CG CUT SHEET

CHARACTERISTICS

- Available in 4’x4′ (1220mm x 1220mm) and 4’x8′ (1220mm x 2440mm) panels in thicknesses of 1″ (25mm) to 4.5″ (114mm)

- ASTM C 1289 Type II, Class 2 Grade 2 (20 psi) or Grade 3 (25 psi)

APPLICATIONS

- Specified for Single-Ply membranes (Ballasted, Mechanically Attached and Fully Adhered), BUR, Modified Bitumen, Coal-Tar

TESTING

Codes and Compliances

- ASTM C 1289 Type II, Class 1 Grade 2 (20 psi) or Grade 3 (25 psi)

- International Building Code (IBC) Chapter 26

- State of Florida Product Approval Number FL 5968

- Miami Dade County Product Control Approved

Underwriters Laboratories Inc Classifications

- UL 1256

- Insulated Metal Deck Construction Assemblies – No. 120, 123, 292

- UL 790

- UL 263 Hourly Rated P Series Roof Assemblies

UL Classified for use in Canada

- Refer to UL Directory of Products Certified for Canada for more details

- CCMC 13460-L

- UL Certified for Canada, CAN/ULC-S126, CAN/ULC-S101, CAN/ULC- S107

- CAN/ULC-S704 Type 2, Class 3 (20 psi) or Type 3, Class 3 (25 psi)

Factory Mutual Approvals

- FM 4450, FM 4470

- Approved for Class 1 insulated steel deck constructions for 1-60 to 1-270. Refer to FM Approval’s RoofNav for details on specific systems

LEED Potential Credits for Polyiso Use (PRE LEED V4)

For current LEED V4 contribution information go to www.PIMA.org or www.hpanels.com

- Energy and Atmosphere

- Optimize Energy Performance

- Materials & Resources

- Building Life-Cycle Impact Reduction

- Environmental Product Declarations

- Materials Reuse

- Recycled Content

- Construction and Demolition Waste Management

WARNINGS

Insulation must be protected from open flame and kept dry at all times. Install only as much insulation as can be covered the same day by completed roof covering material. Hunter Panels will not be responsible for specific building and roof design by others, for deficiencies in construction or workmanship, for dangerous conditions on the job site or for improper storage and handling. Technical specifications shown in this literature are intended to be used as general guidelines only and are subject to change without notice. For more information refer to the Storage and Handling Technical Bulletin at www.hpanels.com, or refer to PIMA Technical Bulletin No. 109: Storage & Handling Recommendations for Polyiso Roof Insulation at www.polyiso.org.

INSTALLATION

SINGLE-PLY SYSTEMS

Ballasted Single-Ply

H-Shield CG panels are loosely laid on the roof deck. Butt the edges of the insulation panels and stagger the joints. Install the roof covering

according to the manufacturer’s specifications.

Mechanically Attached Single-Ply Systems

H-Shield CG must be secured to the roof deck. Butt the edges of the insulation panels and stagger the joints. Install the roof covering according to the manufacturer’s specification.

Fully Adhered Single-Ply

Each H-Shield CG panel must be secured to the roof deck. Maximum 4’x4′(1220mm x 1220mm) panels of H-Shield CG may be adhered to a

prepared concrete deck or subsequent layers of insulation with a full mopping of hot steep asphalt, insulation adhesive or cold applied mastic. Butt edges and stagger joints of adjacent panels. Install the roof covering according to the manufacturer’s specifications.

BUILT UP, COAL TAR AND MODIFIED BITUMEN SYSTEMS (APP, SBS)

Each H-Shield CG panel must be secured to the roof deck. Maximum 4’x4′ (1220mm x 1220mm) panels of H-Shield CG may be adhered to a prepared concrete deck or subsequent layers of insulation with a full mopping of hot steep asphalt, insulation adhesive or cold applied mastic. Butt edges and stagger joints of adjacent panels. Install the roof covering according to the manufacturer’s specifications.

To achieve optimal thermal performance, Hunter Panels recommends installation of a multi-layer system with staggered joints.

AIA Continuing Education

AIA Continuing Education

DMI is committed to providing you with high-quality expert-level education in accordance with the AIA/CES standards. The courses we offer are designed to meet the needs of architects and typically run one hour in length. All Attendees will earn 1 Learning Unit. Some of the courses offered will meet the Health, Safety, and Welfare (HSW) requirements as well as the Green Building Certification Institute (GBCI) credits.

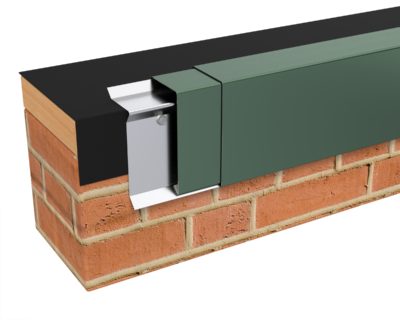

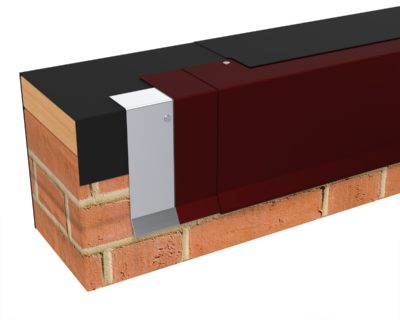

Our Warranties are Second to None

DMI total system warranties protect all aspects of your metal envelope system, whether that be the watertightness of the roof or siding, the Galvalume ® steel, or the durable PVDF KYNAR® finish. When looking at warranties for your system, it is important to note that not all warranties are created equal. DMI warranties ensure the watertightness of all flashing conditions, trims, curbs, valleys, and penetrations. Building owners are protected with a total system warranty - “from the deck up” when using DMI insulation, fasteners, and underlayment. Our warranties are backed-up by a full-service Engineering Department, generating project specific shop drawings. Quality control is monitored by a minimum of two on-site inspections by our Field Technical Inspectors. DMI Total System Warranties give building owners and design professionals confidence that they are receiving the highest quality and most complete warranty available in the industry.