Uses

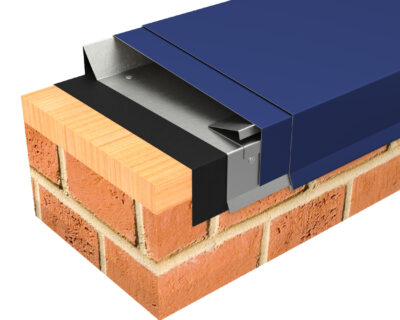

Whole-roof underlayment for metal roofing. Use at eaves, valleys, rakes and around roof penetrations for protection against ice dams and wind-driven rain. For roof slopes less than 3:12 DMI Requires a full layer of Ultra HT on the entire field of the roof.

Features

Ultra HT offers the contractor and property owner these extra features:

- Uniform thickness for dependable protection

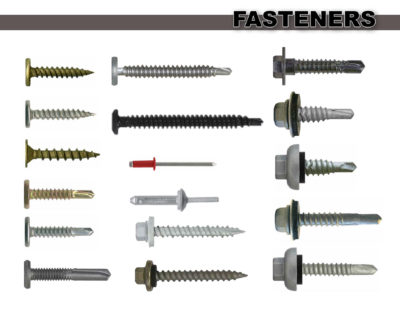

- Self-seals around fasteners including screws and nails

- High elongation, flexible, accommodates expansion and contraction of the substrate

- Compatible with most construction sealants and primers

- Eliminates leaks – multiple layers of protection seals out water

- Rubberized asphalt won’t crack or dry – protects against ice, wind and rain • Aggressively adheres – sticks to plywood, metal and most other building materials for ease of application.

- Non-slip surface and overlap guide lines for easy installation

- White, heat reflective surfaces allows for adhesion directly to Extruded and Poly-Isosyanurate Insulation

Installation

- Surface must be clean, dry and free from oil

- Apply in clear, dry weather at 50°F or above

- Clean, dry wood and metal surfaces do not require priming

- Prime masonry, weathered OSB, exterior grade gypsum roofing products and aged metal surfaces as necessary

- masonry must be fully cured

- Minimum 3” side laps and 6” end laps

- Apply uniform pressure with a 2 – 3” hand roller to the seams and overlaps

- Do not expose to direct sunlight for more than 90 days

- Do not install over solvent-based sealants unless fully cured

- active solvents may liquify bottom adhesive surface

- Installer is responsible for compatibility with caulks and sealants

- Material folded over a roof edge cannot be left exposed, fasten every 6” and cover

Product Data

| Installation Temperature Range | 50°F |

| Material Color | White |

| Roll Width | 36″ |

| Roll Length | 67 ft |

| Carton Weight | 52 lbs |

| Rolls per Carton | 1 |

| Area per Carton | 200 sqft |

| Cartons per Pallet | 30 |

| Max Temp. | 250°F |

Tech. Spec.

| Property | Test Method | Result |

|---|---|---|

| Material Thickness | ASTM D 5147 | 45 Mils Nom. |

| Flexibility @ -20°F | ASTM D 1970 | Pass |

| Vapor Permeance | ASTM E 96 | <0.02 |

| Nail Sealability | ASTM D 1970 | Pass |

| Adhesion to Plywood @ 75°F | ASTM D 903/1970 | >12 lbs/ft |

| Adhesion to Plywood @ 40°F | ASTM D 903/1970 | >2 lbs/ft |

Results based on modified ASTM standards

AIA Continuing Education

AIA Continuing Education

DMI is committed to providing you with high-quality expert-level education in accordance with the AIA/CES standards. The courses we offer are designed to meet the needs of architects and typically run one hour in length. All Attendees will earn 1 Learning Unit. Some of the courses offered will meet the Health, Safety, and Welfare (HSW) requirements as well as the Green Building Certification Institute (GBCI) credits.

Our Warranties are Second to None

DMI total system warranties protect all aspects of your metal envelope system, whether that be the watertightness of the roof or siding, the Galvalume ® steel, or the durable PVDF KYNAR® finish. When looking at warranties for your system, it is important to note that not all warranties are created equal. DMI warranties ensure the watertightness of all flashing conditions, trims, curbs, valleys, and penetrations. Building owners are protected with a total system warranty - “from the deck up” when using DMI insulation, fasteners, and underlayment. Our warranties are backed-up by a full-service Engineering Department, generating project specific shop drawings. Quality control is monitored by a minimum of two on-site inspections by our Field Technical Inspectors. DMI Total System Warranties give building owners and design professionals confidence that they are receiving the highest quality and most complete warranty available in the industry.