PIPE-MASTER®

Flexible Pipe Flashing

PIPE-MASTER ® flexible pipe flashing is designed for the metal roofing industry with weather-tightness and easy installation in mind.

Why PIPE-MASTER®

- Made of tough, but flexible EPDM rubber or high-temperature silicone.

- Clearly marked with the appropriate pipe size assuring easy field cutting and a tight leak free fit.

- Each flashing can be supplied with the proper tube of sealant and fasteners making sure that the installation is complete and leak proof.

DOWNLOAD PIPE-MASTER® CUT SHEET

Sizes

When flashing a steep pitch roof greater than 20 degrees, or a profile with a rib height of 1-1/2” or more, use the next larger size flashing for increased flexibility. Numbers 1 & 3 are closed top.

| Pipe Size – O.D.Material | Flash # | TFC P.N. | Number of Fasteners |

|---|---|---|---|

| 1/4” to 2” EPDM | #1 | 001DEKR | 10 |

| 1-3/4 to 3-1/4 EPDM | #2 | 002DEKR | 13 |

| 1/4” TO 4” EPDM | #3 | 003DEKR | 16 |

| SILICONE | #3 | 003DEKS | 16 |

| 3” to 6” EPDM | #4 | 004DEKR | 19 |

| 4” to 7” EPDM | #5 | 005DEKR | 22 |

| SILICONE | #5 | 005DEKS | 22 |

| 5” to 9” EPDM | #6 | 006DEKR | 26 |

| 6” to 9” EPDM | #7 | 007DEKR | 30 |

| 8” to 13” EPDM | #8 | 008DEKR | 35 |

| SILICONE | #8 | 008DEKS | 35 |

| 10” to 18” EPDM | #9 | 009DEKR | 54 |

| SILICONE | #9 | 009DEKS | 54 |

Colors Available

Stocked in sizes #3 & #5

Other Sizes Available.

Installation

5 easy steps for assuring a leak-free roof.

Step 1

Choose Pipe Opening and Cut.

Step 2

Slide Over Pipe.

Step 3

Form to Roof Profile.

Step 4

Apply sealant to the underside and press against the contours of the panel.

Step 5

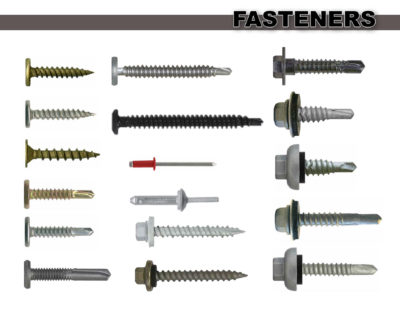

Attach with corrosion resistant self-drilling screws.

We can provide stainless steel hose clamps for additional sealing protection around the top of the flashing.

Ask about our flashing kit that includes flashing, sealant and fasteners.

AIA Continuing Education

AIA Continuing Education

DMI is committed to providing you with high-quality expert-level education in accordance with the AIA/CES standards. The courses we offer are designed to meet the needs of architects and typically run one hour in length. All Attendees will earn 1 Learning Unit. Some of the courses offered will meet the Health, Safety, and Welfare (HSW) requirements as well as the Green Building Certification Institute (GBCI) credits.

Our Warranties are Second to None

DMI total system warranties protect all aspects of your metal envelope system, whether that be the watertightness of the roof or siding, the Galvalume ® steel, or the durable PVDF KYNAR® finish. When looking at warranties for your system, it is important to note that not all warranties are created equal. DMI warranties ensure the watertightness of all flashing conditions, trims, curbs, valleys, and penetrations. Building owners are protected with a total system warranty - “from the deck up” when using DMI insulation, fasteners, and underlayment. Our warranties are backed-up by a full-service Engineering Department, generating project specific shop drawings. Quality control is monitored by a minimum of two on-site inspections by our Field Technical Inspectors. DMI Total System Warranties give building owners and design professionals confidence that they are receiving the highest quality and most complete warranty available in the industry.