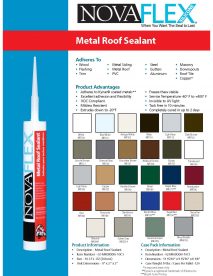

Novaflex®

Metal Roof Sealant

Novaflex ® Metal Roof Sealant provides unbeatable adhesion to metal, coated metals, wood, masonry, PVC and most common construction materials.

Technical Information

- Appearance: Smooth paste

- Service Temperature: – 40ºF to +400ºF

- Adhesion: Excellent to most common building materials

- Consistency: Non-sag

- Gunning Extrusion: Easy to gun

- Flexibility: Good

- Water Resistance: Good

- Not to be submerged

- Exterior Weathering: Excellent

- Aging: Excellent

- Freeze-Thaw Stable:

- Odor: None

- Skin Time:

- 40ºF/40% relative humidity – 40 minutes

- 75ºF/50% relative humidity – 10 minutes

- 95ºF/95% relative humidity – 5 minutes

- Through Time:

- 40ºF/60% relative humidity – 2-3 days

- 75ºF/50% relative humidity – < 24 hrs

- Weight per gallon: 10.2 pounds

- Solids: 97%

DOWNLOAD NOVAFLEX® CUT SHEET

Advantages

- Adheres to Kynar® coated metals*

- Freeze thaw stable

- Excellent adhesion and flexibility

- Service Temperature -40° F to +400° F

- VOC Compliant

- Invisible to UV light

- Mildew Resistent

- Tack free in 10 minutes

- Extrudes down to -20ºF

- Completely cured in up to 2 days

*Kynar is a registered trademark of Arkema Inc

Product Specs

Coverage: 1/4” bead application – 28 linear feet

Specifications: Meets or exceeds ASTM C-920, TT-S-001543A and TT-S-230C

Shelf life: Use product within 18 months from manufacturer’s date. FREEZE THAW STABLE.

User Tips: Not designed for continuous submersion or use below the waterline.

Recommended Use

Recommended For Sealing & Bonding Around

- Wood

- Metal Siding

- Steel

- Flashing

- Metal Roof

- Trim

- Gutters

- PVC

- Aluminum

- Masonry

- Downspouts

Clean Up: Clean tools with toluene or mineral spirits before it dries. After setting, excess sealant must be cut or scraped away. Follow solvents vendor’s precautions.

Not Recommended For

- Surface temperature below 0ºF or exceeding 120ºF during installation

- Surfaces continuously immersed in water

- Building materials that bleed oils, plasticizers or solvents that may affect adhesion

- Frost-laden or wet surfaces

- Completely confined joints or if the sealant is intended to be painted

Limited Warranty: Satisfaction guaranteed when handled and applied according to label instructions.

Product Info.

- Description – Metal Roof Sealant

- Item Number – 02-MR0XXX0-10C1

- Size – 10.3 FL. OZ (304 mL)

- Unit Dimensions – 9” x 2“ x 2”

Case Pack

Case Pack Information

- Description – Metal Roof Sealant

- Item Number – 02-MR0XXX0-10C1

- Dimensions – 11 15/16“ x 9 15/16” x 8 1/8“

- Case Weight 10 lbs. / Cases Per Pallet -120

- 12 Tubes per box

AIA Continuing Education

AIA Continuing Education

DMI is committed to providing you with high-quality expert-level education in accordance with the AIA/CES standards. The courses we offer are designed to meet the needs of architects and typically run one hour in length. All Attendees will earn 1 Learning Unit. Some of the courses offered will meet the Health, Safety, and Welfare (HSW) requirements as well as the Green Building Certification Institute (GBCI) credits.

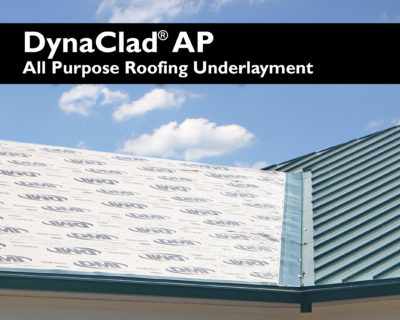

Our Warranties are Second to None

DMI total system warranties protect all aspects of your metal envelope system, whether that be the watertightness of the roof or siding, the Galvalume ® steel, or the durable PVDF KYNAR® finish. When looking at warranties for your system, it is important to note that not all warranties are created equal. DMI warranties ensure the watertightness of all flashing conditions, trims, curbs, valleys, and penetrations. Building owners are protected with a total system warranty - “from the deck up” when using DMI insulation, fasteners, and underlayment. Our warranties are backed-up by a full-service Engineering Department, generating project specific shop drawings. Quality control is monitored by a minimum of two on-site inspections by our Field Technical Inspectors. DMI Total System Warranties give building owners and design professionals confidence that they are receiving the highest quality and most complete warranty available in the industry.